By becoming a member of our site, you can add the content you like to your favorites, and present the content you have produced or liked on the internet to our site visitors with the send content option.

Zaten bir üyeliğiniz mevcut mu ? Giriş yapın

By becoming a member of our site, you can add the content you like to your favorites, and present the content you have produced or liked on the internet to our site visitors with the send content option.

You Can Benefit from All Options Exclusive to Our Members by Registering

Next Content:

Education and Development in the Context of the Middle East Project

- Home Page

- #Automation

- The Role of Robotics in Industry 4.0: Automation and Efficiency

The Role of Robotics in Industry 4.0: Automation and Efficiency

In the era of Industry 4.0, characterized by the integration of digital technologies into manufacturing processes, robotics plays a pivotal role in revolutionizing industrial operations. Robotics, alongside other advanced technologies such as artificial intelligence (AI), internet of things (IoT), and big data analytics, drives automation and efficiency in modern manufacturing environments.

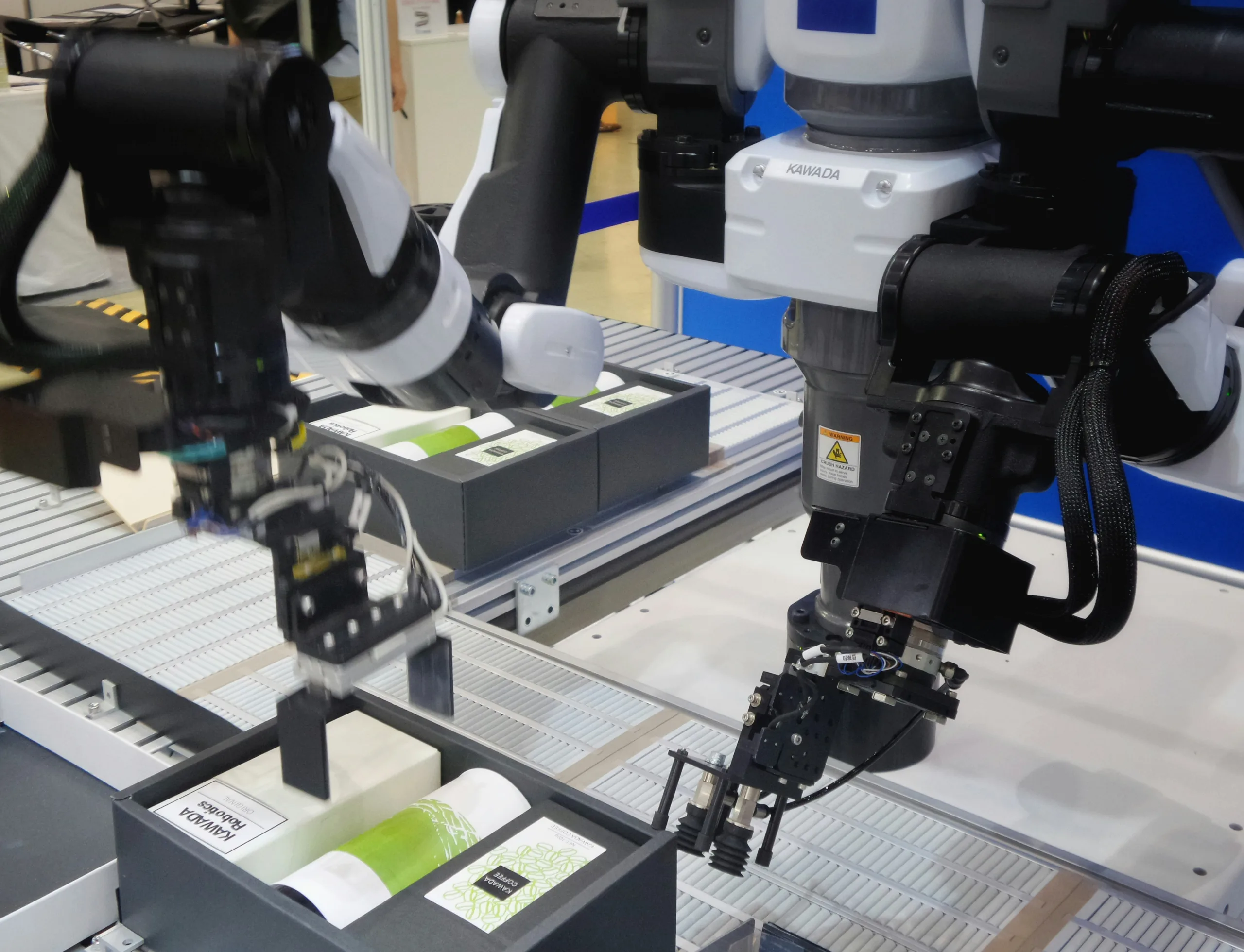

Robots have evolved from their traditional role of performing repetitive tasks on assembly lines to becoming versatile and intelligent collaborators in industrial settings. These next-generation robots, equipped with advanced sensors, actuators, and AI algorithms, are capable of performing complex tasks with precision and adaptability.

One of the key advantages of robotics in Industry 4.0 is automation. Robots can automate various manufacturing processes, reducing the need for manual intervention and minimizing human error. This automation leads to increased productivity, higher quality output, and lower operational costs for manufacturers.

Moreover, robots enhance efficiency by streamlining production workflows and optimizing resource utilization. They can work around the clock without fatigue, leading to continuous operation and faster turnaround times. Additionally, robots can be programmed to perform tasks with consistency and repeatability, ensuring uniformity in product quality.

In the context of Industry 4.0, robotics is not limited to traditional industrial robots confined to fixed locations. Collaborative robots, or cobots, are designed to work alongside human workers in shared workspaces. These cobots are equipped with advanced safety features, such as sensors that detect human presence and automatically stop or slow down operations to prevent accidents. Collaborative robotics enables flexible and adaptive manufacturing processes, where humans and robots collaborate seamlessly to optimize productivity and efficiency.

Furthermore, robotics facilitates the implementation of agile manufacturing systems capable of responding quickly to changing market demands and production requirements. With the ability to reconfigure and reprogram robots for different tasks, manufacturers can easily adapt their production processes to accommodate customization, small batch sizes, and rapid product iterations.

The integration of robotics into Industry 4.0 also presents opportunities for upskilling and reskilling the workforce. As robots take over routine and mundane tasks, human workers can focus on more value-added activities that require creativity, problem-solving, and critical thinking. This shift towards human-robot collaboration necessitates investment in training programs and educational initiatives to equip workers with the skills needed to operate, program, and maintain robotic systems.

In conclusion, robotics plays a transformative role in Industry 4.0 by driving automation and efficiency in manufacturing. As manufacturers embrace the opportunities presented by advanced robotics technologies, they can unlock new levels of productivity, quality, and agility, positioning themselves for success in the digital age of manufacturing.

We offer our respects and wish you a good reading. – Who Learns What? Team!

Dont forget the comment here mate! 🙂 you can connect us!

- On-Site Comments